Desperate Times

Posted by estiator at 9 November, at 11 : 56 AM Print

MANAGING FOR SUCCESS By CONSTANTINE N. KOLITSAS Business Coach

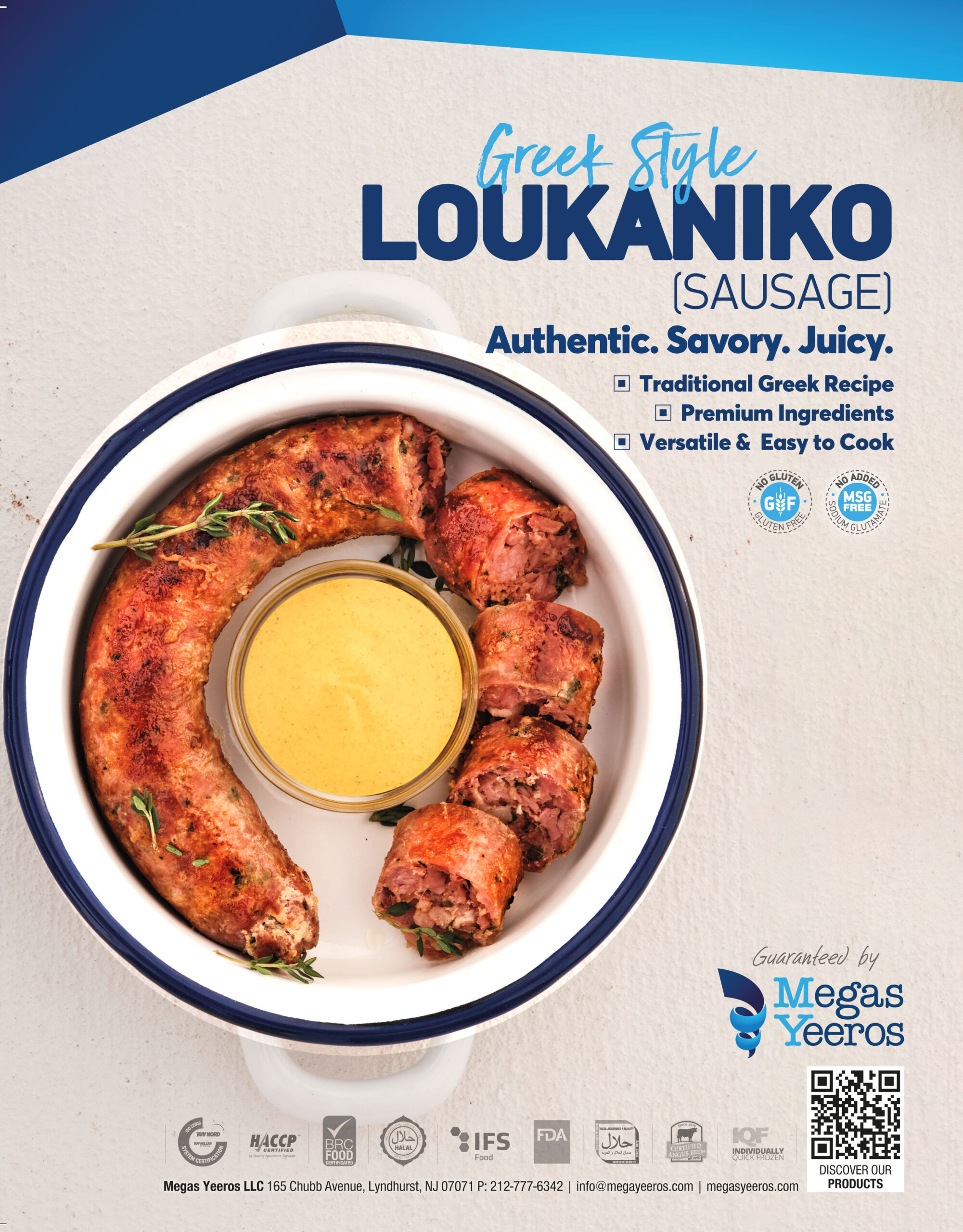

These are strange times for the restaurant industry, some might even say desperate times: Labor costs are through the roof (and the same goes for food costs); gas prices and escalating inflation have consumers skittish about spending; and the supply chain is schizophrenic, with shortages spanning from tequila to takeout boxes, and from chicken wings to pork sausages. However, if the old adage suggests that desperate times call for desperate measures, I say, hogwash. Sure, we need to swerve, switch up our pace, and mix up our batting order from time to time; but we can’t (and should not even when we think we can) make moves out of desperation that we mistakenly believe our customers won’t notice. It can be moves like those that signal the game is over.

When it comes to desperate measures, perhaps the biggest temptations fall under the purchasing umbrella. And trust me, it’s not hard to understand the thought processes behind such measures. Often, they are justified as a hedge against rising food costs, some- times as a supply chain redirect, and every once in a while to satisfy higher delivery minimums (a supplier measure that came about as a result of mostly COVID-induced driver shortages).

I get it. Restaurant owners are wired to purchase wisely. And a good purchasing strategy has several approaches in addition to price. And here, I’ll relay one simple incident in which a bad decision is made with the best of intentions, and how that one decision has negative connotations across a spectrum of restaurant concerns…

I was speaking with one pizzeria owner about a company he stopped doing business with because they had raised their delivery minimums to 25 cases. The supplier was not competitive in enough areas to justify them getting such large weekly orders, so he had stopped doing business with them except for the purchase of dishwasher chemicals, which were obligated under a leasing agreement (this company supplied the dish- washing machine). He was bemoaning the fact that he was in need of chemicals and would have to fill out his next order with some other generic items, as he didn’t want to purchase 25 cases of chemicals (they are expensive and would cause him to sit on excessive inventory dollars). Not wanting to order produce that he had already ordered and which would sit and wither, he decided he would add to his order six cases of mozzarella cheese that he used to top his pizzas.

Before switching products about two years ago, in a strategic move that he had contemplated and studied over a span of three months, he had ordered the cheese through them. In his mind, he was not doing anything desperate but, rather, just going back to the old product for a short period of time. In my mind, however, this move was harmful in several ways. First, the product he had switched to, although more highly priced, was less expensive, as the cheese melted in such a way as to be able to use about 50 percent less than with the old cheese (which he was about to order again). Additionally, the old cheese had to be shredded through the grater attachment of his dough mixer, whereas the new cheese came in to the restaurant pre-shredded. Assuming his staff’s time was filled, this meant additional labor hours would have to be expended to shred the cheese, a cost that had been pulled from the equation with the change over the previous year.

It’s not always about what product is best, but about maintaining consistency so your customers keep coming back for the product they like and trust.

Next, there are quality issues that would be result from this “desperate measure.” Because it had to be shredded in-house, the cheese would sit in covered bus bins from the time it was shredded until the time it was used. Previously, his pizza team would shred cheese three times a week. Because cooks tend to over-prep, that means some of the cheese would sit in those bus tubs in the walk-in cooler for three or four days, absorbing the refrigerator odors. The pre-shredded cheese he had switched to comes packaged in five-pound bags, which are opened as needed. Also, as the old cheese sat in the bus tubs, it would continue to settle and become more dense. This made it more difficult to spread on the pizza, slowing down the production line, and causing an uneven cheese coat on the pizza as it baked. Clearly, the quality proposition of the new cheese would be completely negated with even the temporary switch.

Finally, even if the shredding was managed perfectly (an oxymoron of a statement if there ever was one), customers would notice the switchback. They may not be able to pinpoint what was different about the pizza, but regular customers would very likely notice that “something changed.” And here it makes no difference if the old cheese was inferior, superior, or just as good. It’s different. And we all know that because one person’s taste is different than the other’s, it’s not always about what product is best, but about maintaining consistency so your customers keep coming back for the product they like and trust.

Don’t let the challenges we face in our business keep you from holding up your end of the consistency bargain.